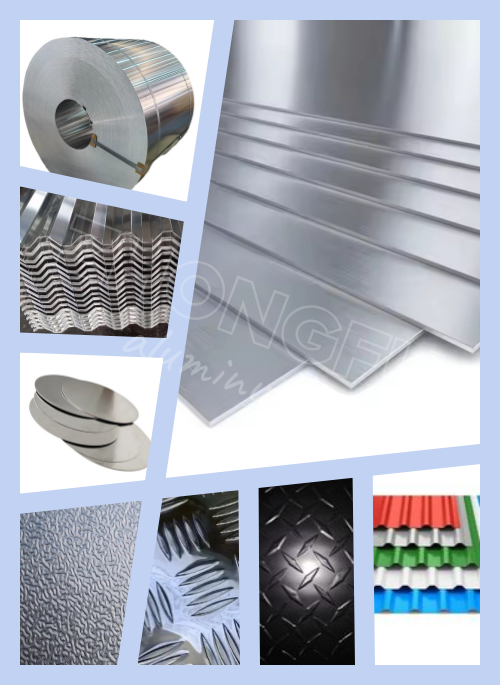

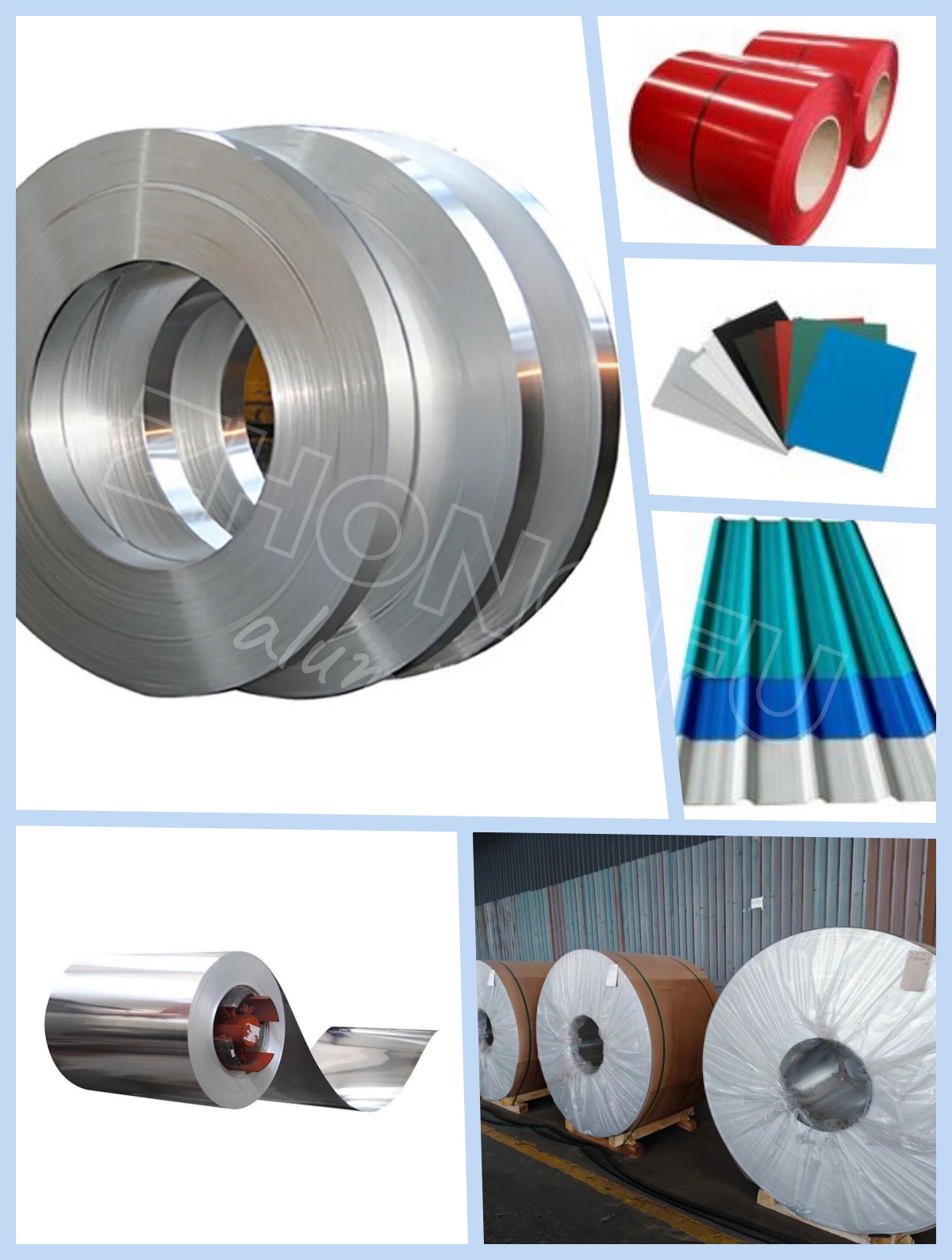

In the vast field of industrial aluminum materials, 1-series aluminum sheets occupy a crucial position with their unique advantages. Boasting high purity (aluminum content ≥ 99.00%), excellent workability, and outstanding corrosion resistance, they are highly favored across various industries. Today, we will take you deep into the available processing methods for 1-series aluminum sheets, common defects during processing and their solutions, while showcasing our company’s national standard-compliant aluminum sheets and extensive business scope. We look forward to cooperating with potential clients.

1 Comprehensive Analysis of 1-Series Aluminum Sheet Processing Techniques

1.1 Cutting Processing

Laser Cutting: Utilizes a high-energy-density laser beam to instantly melt or vaporize the material being cut. Suitable for common 1-series aluminum sheets such as 1100 and 1060. It offers extremely high cutting precision with sharp engraving angles (minimum R-angle up to 0.02mm) and narrow slits (minimum 0.5mm), enabling the creation of intricate and delicate patterns. As a non-contact processing method, it avoids mechanical extrusion or stress on the aluminum sheet, eliminating "tool marks", surface damage, and material deformation.

Sawing: Cuts the aluminum sheet through the rotation or reciprocating motion of a saw blade. Simple to operate, it is ideal for scenarios requiring rapid mass cutting without ultra-high precision requirements, such as preliminary length cutting of aluminum sheets in the architectural decoration industry.

1.2 Forming Processing

Rolling: The fundamental forming process for 1-series aluminum sheet production. Aluminum ingots are rolled into sheets of varying thicknesses and widths via rolling mills. This process effectively improves the internal structure of the aluminum sheet and enhances material performance. By controlling rolling parameters, products ranging from thin sheets to medium-thick plates can be manufactured, widely used in applications such as building exterior wall panels and electronic radiator substrates.

Bending: Applies pressure to 1-series aluminum sheets using a bending machine to form the desired angles and shapes. Thanks to their excellent ductility, 1-series aluminum sheets are easy to bend. They are commonly used in manufacturing side panels of various boxes and containers (e.g., wine tanks, pressure vessels) as well as shaped components in architectural decoration.

1.3 Surface Treatment

Oxidation Treatment: Forms a dense aluminum oxide protective film on the surface of 1-series aluminum sheets, further enhancing their corrosion resistance and wear resistance. After anodizing, the surface hardness of the aluminum sheet increases, effectively resisting daily scratches. Chemical oxidation, on the other hand, is relatively simple to operate and cost-effective, suitable for general industrial scenarios with certain corrosion resistance requirements.

Coating Treatment: Includes fluorocarbon coating, polyester powder coating, baking paint coating, etc. Fluorocarbon coating offers exceptional weather resistance, corrosion resistance, and self-cleaning properties, making it ideal for projects requiring high appearance durability such as building curtain walls and exterior decorations. Polyester powder coating is more cost-effective with strong coating adhesion and a wide range of colors, widely used in household appliance casings and interior decorations.

2 Common Processing Defects and Solutions

2.1 Surface Bubbles

Defect Characteristics: Irregular circular or strip-shaped cavity protrusions on the aluminum sheet surface with smooth edges, asymmetric distribution on the upper and lower sides of the sheet, and random spacing.

Causes: Uneven or unclean ingot surface with deep segregation nodules; insufficient milling amount or surface indentations/cutter marks; emulsion or air trapped between the clad sheet and ingot; excessive ingot heating temperature or duration; overly high heat treatment temperature.

Solutions: Ensure ingot surface quality by increasing milling amount and removing surface defects; optimize processing procedures to prevent emulsion or air entrapment; strictly control heating and heat treatment temperatures and durations.

2.2 Burrs

Defect Characteristics: Short, thin filaments or sharp, thin metal projections of varying sizes on the edges of aluminum sheets after shearing.

Causes: Dull shear blades, poor lubrication, improper adjustment of gap and overlap.

Solutions: Regularly replace worn shear blades, ensure adequate lubrication, and precisely adjust shear blade gap and overlap.

2.3 Scratches

Defect Characteristics: Single strip-shaped marks on the aluminum sheet surface caused by relative sliding between sharp objects and the sheet.

Causes: Aluminum adhesion on hot rolling mill roller tables or guide plates; sharp objects on cold rolling mill guide plates or flattening rolls; sheet surface scratches from plate corners during finishing; scratches from foreign objects during packaging.

Solutions: Timely remove aluminum adhesion from equipment, inspect and repair equipment components, and standardize finishing and packaging processes.

3 Company Strength

With years of experience in aluminum sheet production and operation, Jinan Zhongfu Aluminum Co., Ltd. manufactures 1-series aluminum sheets strictly in compliance with national standards (e.g., GB/T 3880 and other relevant standards). Every link from raw material procurement to processing is subject to rigorous quality control. Equipped with advanced production equipment and an experienced technical team, we can accurately control processing parameters to ensure stable and reliable aluminum sheet quality. Our business scope covers the production and sales of 1-series aluminum sheets in various specifications, capable of meeting diverse customer needs.

4 Contact Us

If you are looking for a high-quality 1-series aluminum sheet supplier, please feel free to inquire. Take action and contact us now: [email protected], Whatsapp:+86 17860138617, Wechat:+86 17860138617 or online form to get your customized product solution and quote.