3003 aluminum discs are typical Al-Mn alloy products, favored for their balanced corrosion resistance, moderate strength, and excellent formability. Below is a detailed overview of their chemical composition, mechanical properties, core application fields, and the competitive advantages of choosing Zhongfu Aluminum's 3003 aluminum discs.

I. Chemical Composition

As a classic aluminum-manganese alloy, 3003 aluminum discs take aluminum (Al) as the base metal. The precise chemical composition (by weight percentage, wt%) is as follows:

- Manganese (Mn): 1.0%–1.5% – The core alloying element, which significantly enhances the alloy's mechanical strength and corrosion resistance without compromising formability.

- Silicon (Si): 0.4%–1.0% – Has a moderate impact on the alloy's processability and structural stability, within a controlled range to ensure product consistency.

- Copper (Cu): 0.05%–0.20% – A trace element that optimizes the alloy's hardness and wear resistance, improving overall performance in precision processing scenarios.

- Iron (Fe): ≤0.70% – An unavoidable impurity, strictly controlled to prevent adverse effects on the alloy's ductility and surface quality.

- Zinc (Zn): ≤0.10% – Has minimal influence on the alloy's core properties, with content strictly limited to ensure stability.

- Other impurities: Single impurity ≤0.05%, total impurities ≤0.15% – Strictly controlled to guarantee the purity and reliability of the alloy.

II. Mechanical Properties

The mechanical properties of 3003 aluminum discs are closely related to processing tempers and heat treatment conditions. Key performance indicators for common tempers are listed below:

- Tensile strength (σb): 150–350 MPa (annealed state, O temper); 200–250 MPa (half cold-worked hardened state); 250–300 MPa (full cold-worked hardened state).

- Yield strength (σ0.2): 115–150 MPa (annealed state); 150–200 MPa (after cold-worked hardening), providing reliable load-bearing capacity for structural applications.

- Elongation (δ): 15%–35% (annealed state), ensuring excellent formability for stamping, spinning, and deep-drawing processes; 5%–15% (after cold-worked hardening), balancing strength and shaping performance.

- Brinell hardness (HB): 50–70 (annealed state), suitable for scenarios requiring high ductility; 80–120 (after cold-worked hardening), enhancing wear resistance for heavy-duty applications.

III. Application Fields

With outstanding corrosion resistance, moderate mechanical strength, and superior processability, 3003 aluminum discs are widely applied in high-growth and traditional industries. Core application scenarios include:

1. New Energy Vehicle Industry

Used for manufacturing battery casings, battery covers, and automotive water-cooled plate blanks. Its excellent thermal conductivity effectively dissipates heat, while corrosion resistance ensures long-term battery safety in complex vehicle environments.

2. Solar Photovoltaic Industry

Applied in the production of solar panel frames, brackets, and heat dissipation components. The combination of corrosion resistance (adapting to outdoor exposure) and thermal conductivity improves the efficiency and service life of photovoltaic modules.

3. Wind Power Generation Industry

Utilized for manufacturing structural parts of wind turbine blades and auxiliary components. High strength and resistance to harsh outdoor environments (humidity, ultraviolet radiation) ensure stable operation of wind turbines.

4. Energy Storage Industry

Used to produce energy storage battery enclosures and structural components. Lightweight properties reduce the overall weight of energy storage systems, while corrosion resistance meets the long-term service requirements of stationary and mobile energy storage scenarios.

5. Chemical Equipment Industry

Applied in manufacturing chemical containers, pipeline components, and reactor blanks. Excellent resistance to mild chemical media erosion ensures the safe and stable operation of chemical equipment.

6. Architectural Decoration Industry

Used for producing building curtain wall components, door/window decorative panels, and decorative strips. Aesthetic appearance, durability, and easy forming make it adaptable to diverse architectural styles.

7. Electronics & Electrical Industry

Utilized for manufacturing electronic device casings, radiator blanks, and circuit board substrates. Good electrical conductivity and corrosion resistance meet the performance and reliability requirements of electronic products.

Ⅳ. Reasons for Choosing Zhongfu Aluminum 3003 Aluminum Discs

1. Rigorous Quality Assurance

We strictly comply with international standards (ASTM, JIS, GB) and implement full-process quality control – from high-purity raw material procurement to finished product inspection. Each batch of 3003 aluminum discs is accompanied by a detailed test report, ensuring consistent chemical composition and stable mechanical performance.

2. Professional Technical Strength

Our experienced R&D and engineering team provides tailored solutions based on customer needs, including material selection guidance, temper customization advice, and processing technology optimization. We help customers reduce production scrap rates and improve manufacturing efficiency.

3. Stable Production Capacity & Inventory

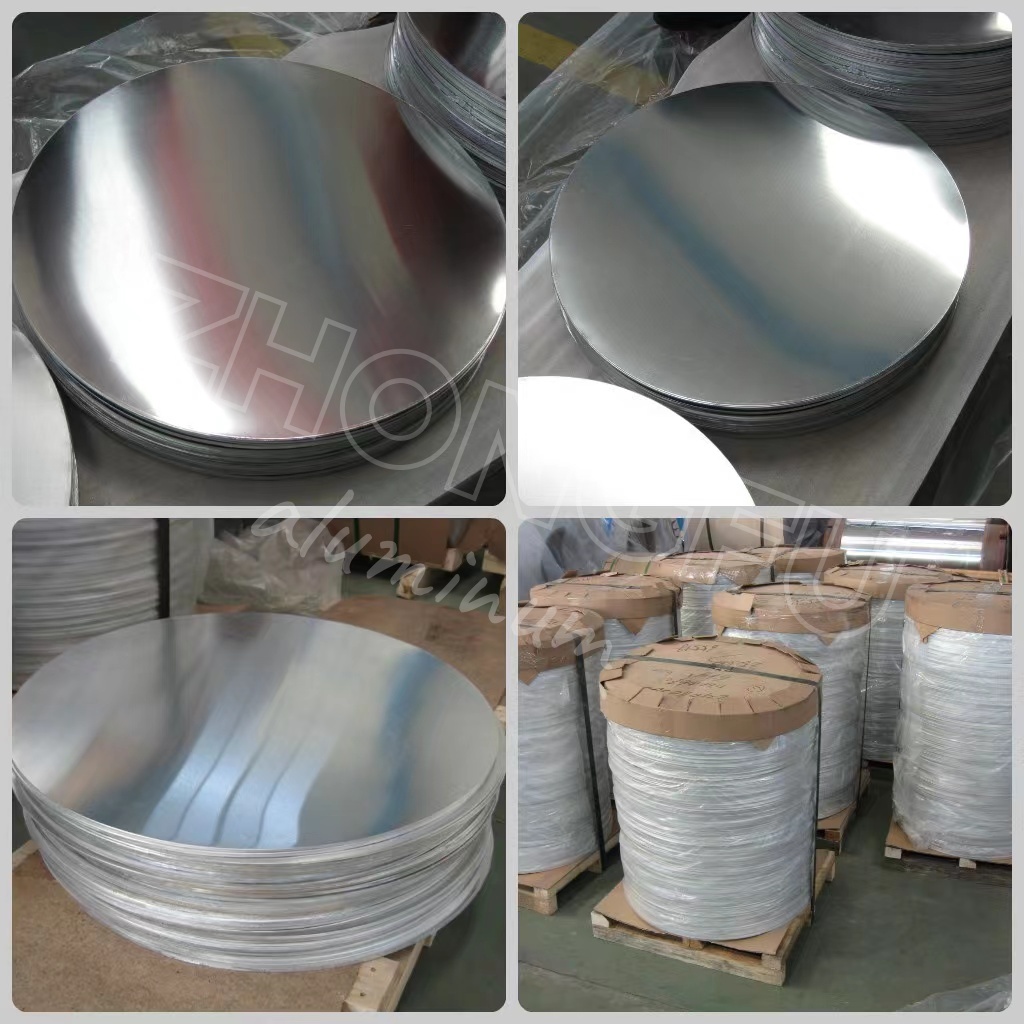

With an annual output of 100,000 tons, we maintain sufficient inventory of common specifications of 3003 aluminum discs (diameter: 100–2000mm; thickness: 0.3–10mm). We can quickly respond to emergency orders, ensuring stable supply chain support for global customers.

4. Factory-Direct Pricing Advantage

As a source manufacturer, we eliminate intermediate distributor markups, adopting a transparent and reasonable pricing system. Customers can reduce procurement costs by 5–15% compared to trading companies, while enjoying high-quality products.

5. Flexible Customization & One-Stop Service

We support customized production for diameter, thickness, temper, and surface treatments (e.g., anodizing, painting, fluorocarbon spraying). Our one-stop service covers pre-sales consultation, order customization, production scheduling, international logistics (sea/air/land transport), and after-sales tracking, ensuring a seamless cooperation experience.

6. Proven Global Reputation

We serve over 100 distributors and 3,000+ end customers worldwide, exporting products to more than 30 countries and regions (including the USA, EU, Southeast Asia, and the Middle East). With a customer repurchase rate of over 85%, we have won wide market recognition through honest operation and high-quality services, and hold ISO9001, SGS, and BV certifications.

Ready to Source High-Quality Aluminum Discs?

Take action and contact us now: [email protected], Whatsapp:+86 17860138617, Wechat:+86 17860138617 or online form to get your customized product solution and quote.