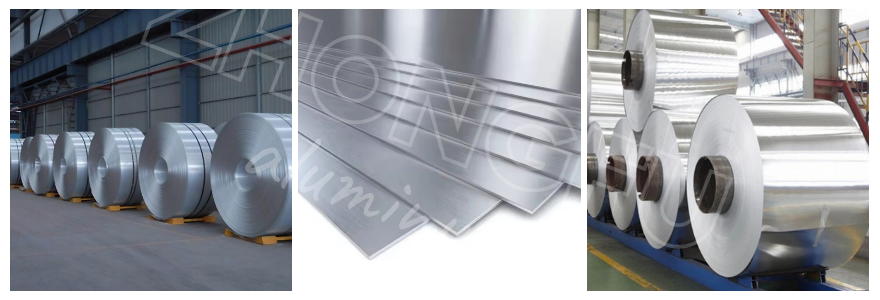

I. Aluminum Sheet and Aluminum Coil Overview

Aluminum sheets and aluminum coils are two of the most common product forms in the aluminum processing industry, widely used in construction, automotive, packaging, industrial equipment and other fields. Both are mainly made of 1xxx/3xxx series aluminum materials, but there are obvious differences in specifications, processing methods and application scenarios. For global procurement customers, correctly distinguishing the two and selecting according to project needs can effectively improve project efficiency and reduce procurement costs.

II. Specification Differences Between Aluminum Sheet and Aluminum Coil

In terms of specification characteristics, aluminum sheets are flat-plate products cut into fixed lengths and widths after rolling, with clear size standards. The thickness of common aluminum sheets ranges from 0.2mm to 50mm, and the width and length can be customized according to customer needs, such as 26 gauge (about 0.406mm) thin aluminum sheets for building decoration and 3mm medium-thick aluminum sheets for industrial equipment. Aluminum coils are coiled products formed by continuous rolling, without fixed length, and can be cut arbitrarily according to actual needs. The thickness of aluminum coils is mostly between 0.1mm and 10mm, and the width is usually 1000mm-1600mm, which is suitable for large-batch continuous processing.

III. Application Scenario Adaptation

In terms of application scenario adaptation, aluminum sheets are more suitable for scenarios that require direct use or small-batch processing. For example, in the construction field, aluminum sheets are used as building facades, decorative panels and industrial operation platforms; in the hardware industry, aluminum sheets are cut and punched into various components; in the packaging field, thick aluminum sheets are used to make chemical tanks and food packaging boxes. Aluminum coils are more suitable for large-area construction projects and continuous production scenarios, such as large-scale building roof projects using 3xxx series aluminum coils cut into aluminum roofing sheets, and packaging industry using 1xxx series aluminum coils processed into aluminum foils.

IV. Processing Efficiency and Cost Comparison

In addition, there are differences in processing efficiency and cost between aluminum sheets and aluminum coils. Aluminum coils have high production efficiency and low unit cost, which is suitable for large-batch procurement; aluminum sheets need additional cutting processes, and the cost is slightly higher, but they can save processing time for small-batch projects. When selecting, it is necessary to comprehensively consider the project scale, processing requirements and cost budget.

Ⅴ. Main Products

Jinan Zhongfu Aluminum Co., Ltd. has more than 13 years of experience in the aluminum industry. In addition to 3xxx series aluminum tiles, our main products cover 1xxx/3xxx series aluminum sheets/coils, aluminum foils, embossed aluminum sheets/coils, 1xxx/3xxx series aluminum discs, color-coated aluminum sheets/coils, aluminum strips and customized aluminum products. These products are widely used in construction, automotive, packaging, marine, aerospace, industrial equipment and other fields. We adhere to the concept of "quality first, customer-oriented" and provide global customers with one-stop aluminum product solutions.

Ready to Source High-Quality Aluminum Sheets & Coils?

Take action and contact us now: [email protected], Whatsapp:+86 17860138617, Wechat:+86 17860138617 or online form to get your customized product solution and quote.